Additive Fertigung

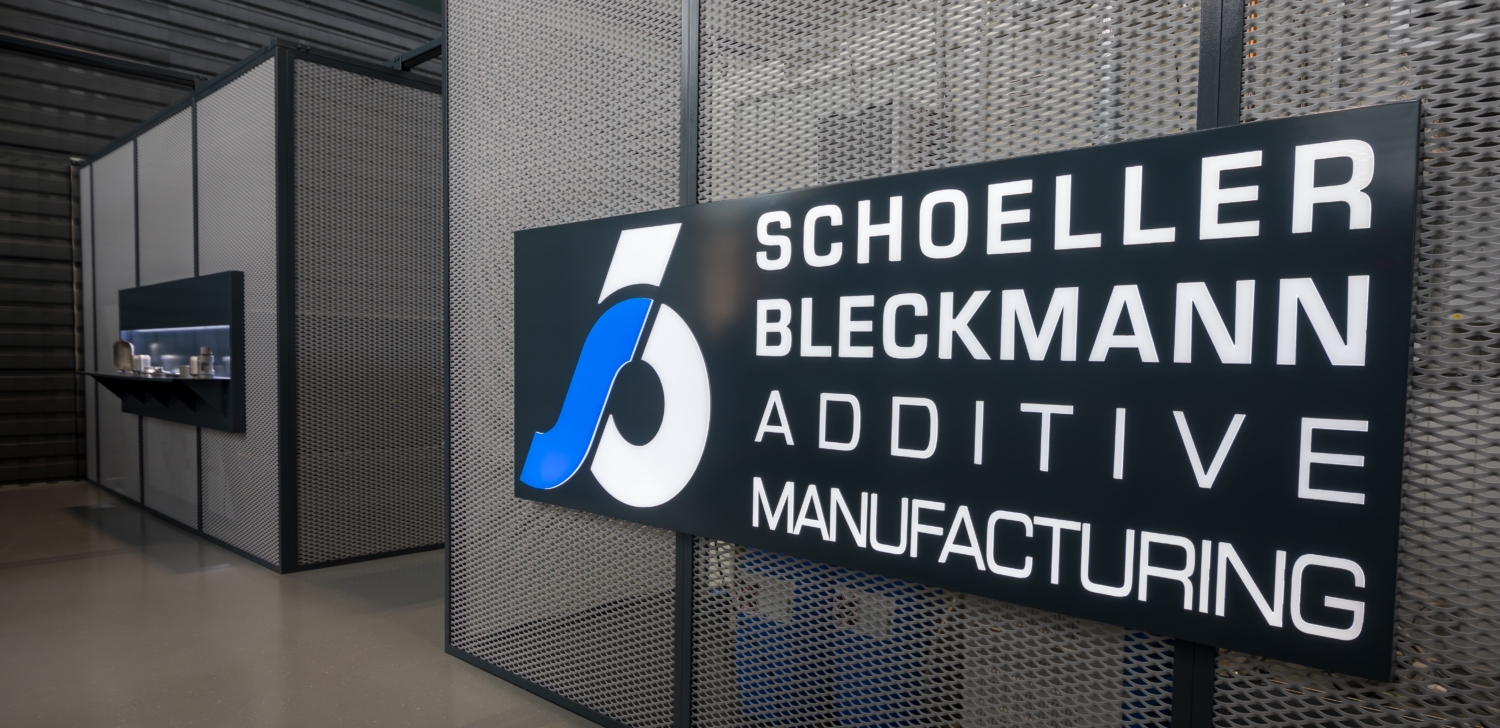

ERSTER VELO3D SAPPHIRE XC DRUCKER IN EUROPA

IN UNSEREM 3D KOMPETENZ-ZENTRUM

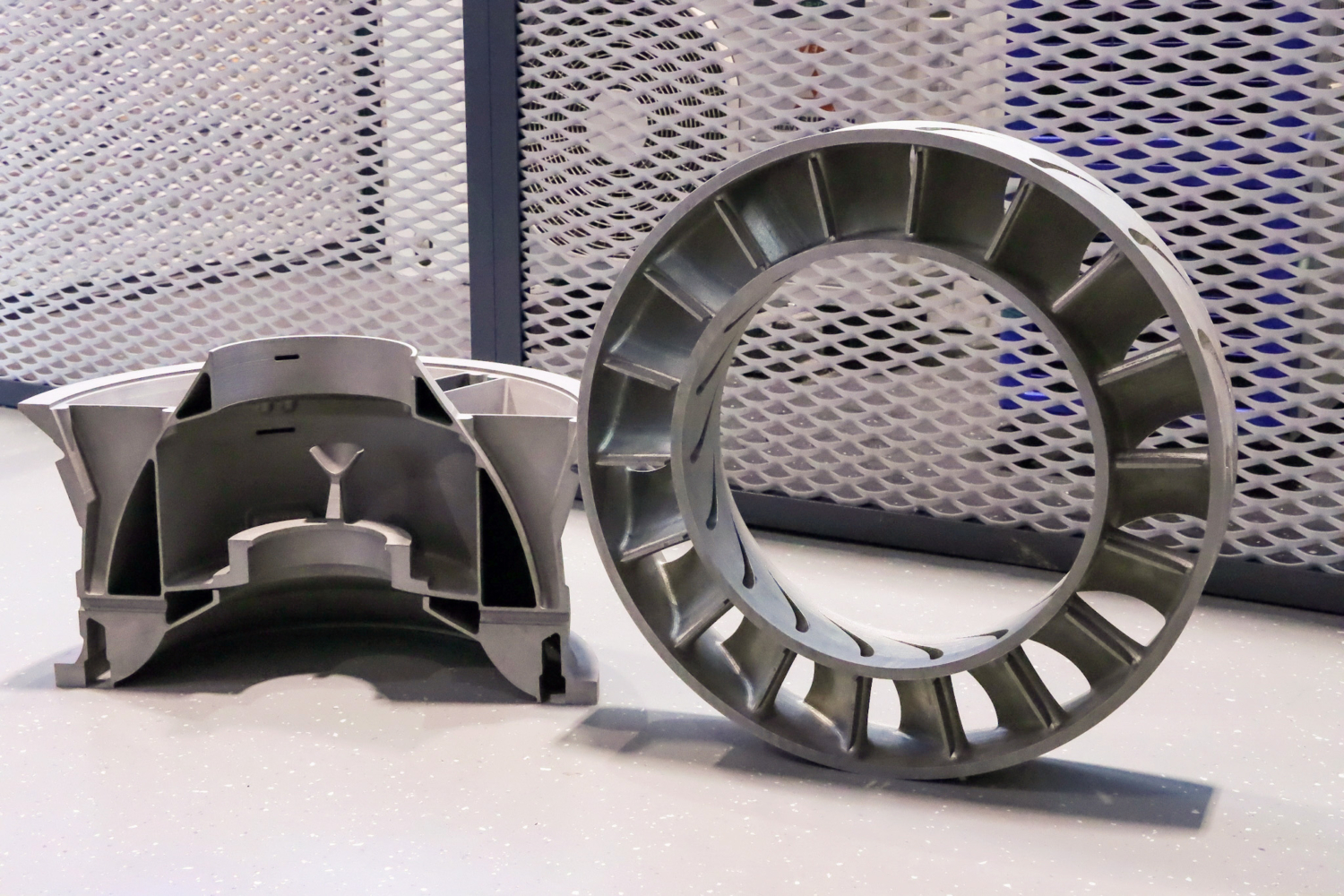

Druckgrößen bis zu 600 mm Durchmesser und 550 mm Höhe

Vom Konzept zum komplexen Bauteil in unserer One-Stop-Produktion.

Sie bringen die Idee, wir liefern die fertige Lösung!

Mehr Informationen zum Prototyping finden Sie hier.

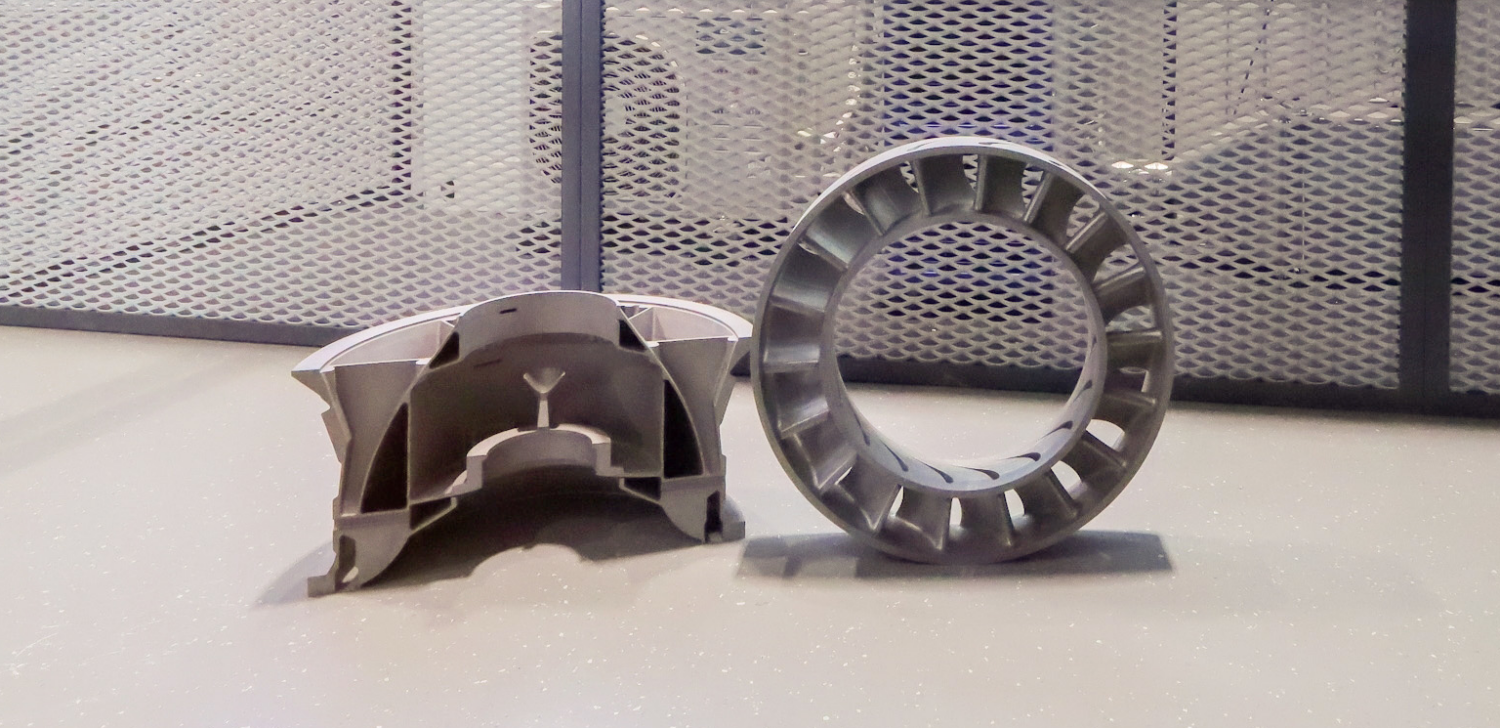

Grenzenlos in der Herstellung und Gestaltung von Metallkomponenten

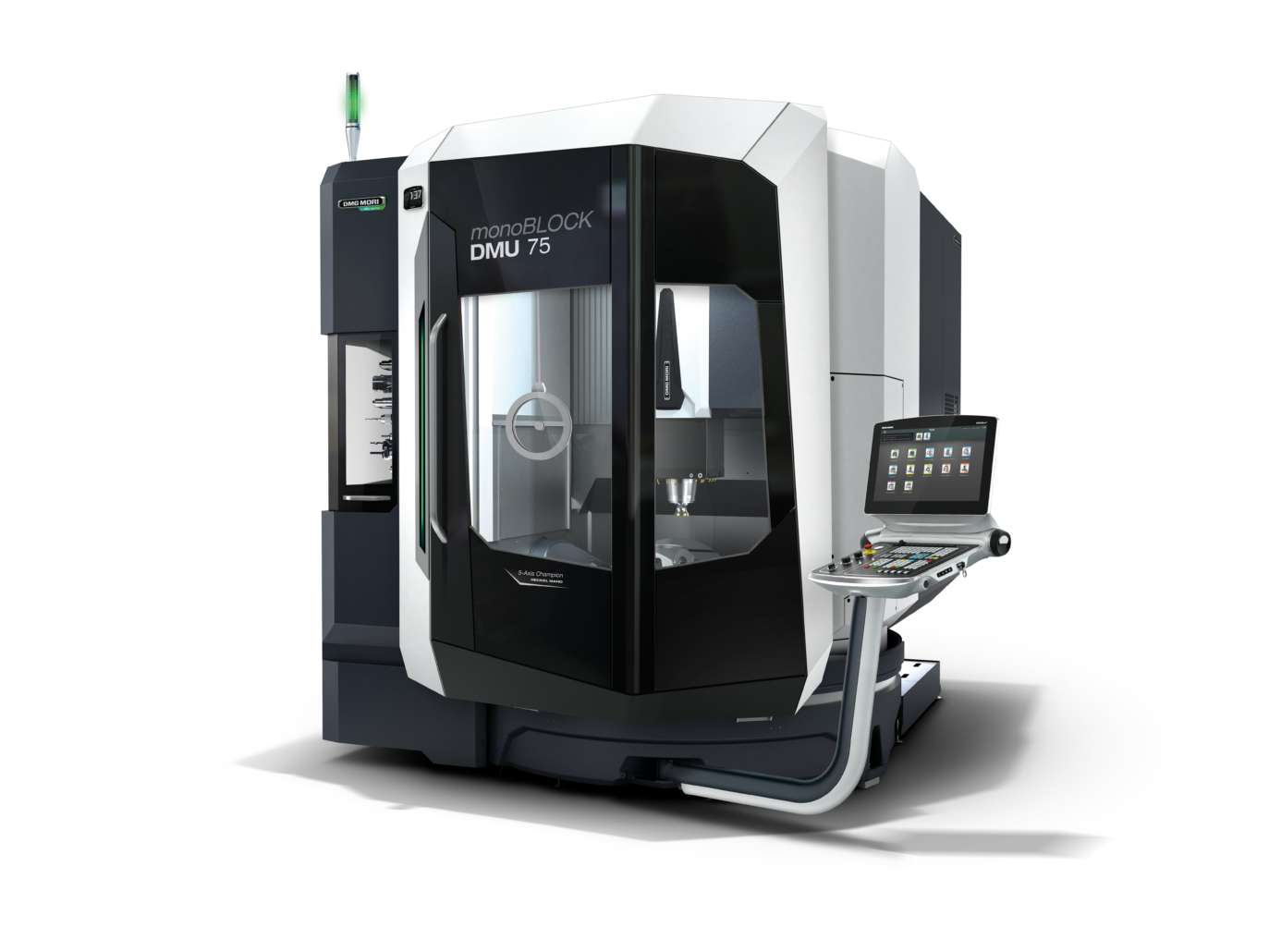

Wir sind ein führendes Produktionsunternehmen mit einzigartigen Technologien und jahrzehntelanger Erfahrung in der Herstellung von unternehmenskritischen Komponenten. Als erstes Unternehmen in Europa mit einem Sapphire XC 3D-Drucker im Maschinenpark sind wir sehr stolz darauf, bemerkenswerte Fähigkeiten für zahlreiche Geschäftsbereichen anbieten zu können. Wir bieten zusätzlich Materialprüfung, Zerspanungsmöglichkeiten wie CNC Drehen / Fräsen, Wärme / Oberflächenbehandlungen für die exakte Nachbearbeitung von 3D-Komponenten, welche wir somit gebrauchsfertig liefern können – wir sind Ihr One-Stop-Shop! Profitieren Sie von unserer Erfahrung in der Herstellung von High-Tech-Komponenten für die anspruchsvolle Öl- und Gasindustrie, unserem ursprünglichen Hauptgeschäftsfeld.

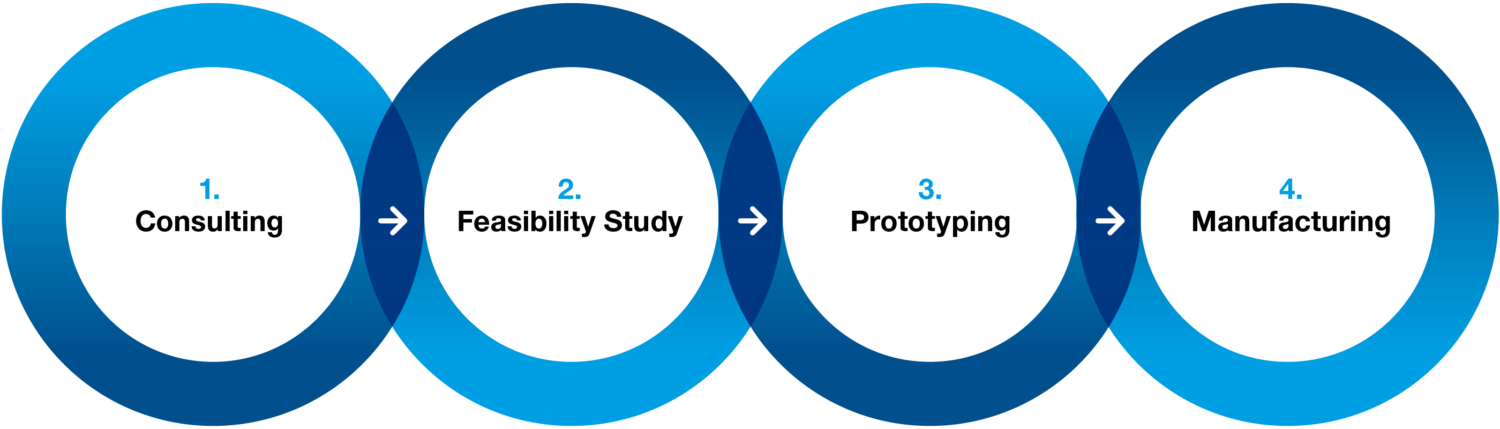

In unserem Kompetenz-Zentrum für additive Fertigung betreuen wir Ihr 3D-Druckprojekt von der Beratung über die Machbarkeitsstudie, das Prototyping bis hin zur Serienfertigung. Unsere 3D-Drucker sind ausgerichtet, um große Metallkomponenten mit einer Größe von bis zu 600 mm Durchmesser und 550 mm Höhe zu drucken.